Farming

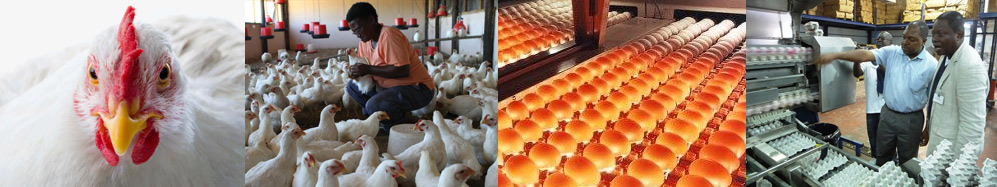

Within our agricultural, feed milling and production processes, our world-class animal welfare and food safety assurance programs ensure sterile and pathogen-free raw materials and production environments. As an integrated broiler producer, CAPS focuses on the entire growing cycle, allowing us to oversee every step of the farming and production process. Bio-security, flock health, body-weight control and uniformity management are core issues driving the optimal performance of our operations.

We produce three generations of birds in order to provide consistent high-quality broiler meat. Birds are farmed at grandparent, parent (broiler-breeder) and broiler level.

Grandparent Farms

CAPS grandparent farms regularly import pure genetic stock from Cobb 500. Fully-grown birds are transferred to laying sites where for the next 10 months they produce eggs. Eggs are then collected and transported to the hatchery.

Broiler Farms

Broilers are birds that are grown purely for meat production by providing them with an energy and protein rich, highly nutritious diet.

Feeding

All CAPS chickens are grain fed. As chickens are omnivores their feed contains a balance of grain and protein sources – consisting of about 70% maize and 30% protein.

Antibiotics

Antibiotics are only used in treatment as stipulated under the SAPA Code of Practice, the Fertilisers and Farm Feeds Agricultural Act 36 of 1947 and the Medicines and Related Substances Control Act 101 of 1965. These regulations prohibit the unnecessary administration of antibiotics to healthy flocks. Should we need to use antibiotics, we adhere to the recommended withdrawal period of five to six days prior to slaughter.

Slaughter

CAPS ensures that all our birds are handled as humanely as possible prior to and during slaughter. Our primary plants all operate two slaughter lines throughout the facility to handle fresh and frozen products for the market. This ensures focus, attention to detail and the provision of high quality products to the consumer.